Driven by rapid innovation and rising expectations, the electronics industry stands at the crossroads of smart manufacturing, digital transformation, and sustainability. How do these go hand in hand? Delving deep, Prashant Kumkar from Tata Technologies broke down this transition at the EFY Expo in Pune.

Electronics and smart manufacturing: A mutual drive for progress

We know that electronics not only enable smart manufacturing in factories but that smart manufacturing itself drives progress in electronics component production. These elements complement and reinforce each other rather than being entirely dependent.

World over the industry is experiencing strong growth, with a global compound annual growth rate (CAGR) of around 10%. In India, growth is even higher, often surpassing this benchmark. Against this backdrop, examining the broader trends in smart manufacturing that are reshaping the industrial landscape becomes essential.

Manufacturing trends and technology selection

There are many manufacturing technologies available in the market. However, the real challenge lies in identifying and applying the right technology to address specific industry problems. This process requires significant time, effort, and an understanding of both the technology landscape and aligning it with business priorities.

Some digital technologies, such as PLM, ERP, and MES, and their integration, must be deployed horizontally across the factory, including different departments and functions. While some technologies can be planned on a point-to-point basis, for instance, automating manual processes, material movement, and quality inspection using robots, cobots, AMRs (autonomous mobile robots), and AI-computer vision, it is vital to assess which processes can be digitised, focusing on whether they add value in OpEx reduction and improve quality and safety.

Factory health and performance

To maintain factory performance, industries must track the performance of each machine and piece of equipment, particularly those located at critical stations. Checking key metrics such as availability, performance, and quality (APQ) is vital for achieving overall equipment effectiveness.

Moving towards smart manufacturing environments, this is especially relevant for the electronics sector, which plays a dual role: it transforms internally and enables transformation in other industries, such as automotive, aerospace, and industrial manufacturing. This dual role makes it essential to evaluate the electronics industry from both perspectives.

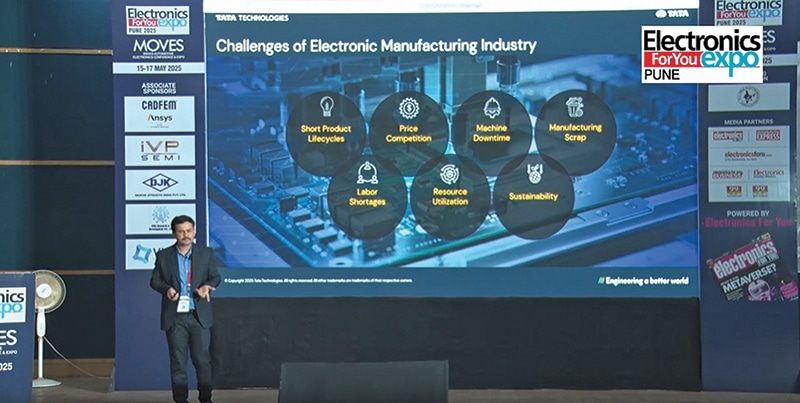

Challenges of the electronic manufacturing industry

- Product life cycles. These have become significantly shorter. Automotive programs that once lasted four to five years are now replaced in one to two years. In the consumer electronics industry, constant demand for new features pressures manufacturers to innovate rapidly.

- Pricing pressures. Competition is intense. Managing costs—not just the final product price but also CapEx and OpEx—is crucial for sustaining profitability.

- Brownfield machines. Factories often have many existing machines that are non-communicating with each other. Replacing old machines is neither feasible nor cost-effective, so retrofitting with IoT devices, sensors, or similar upgrades is necessary to enable meaningful analytics.

- Scrap management. Due to critical operations and precision manufacturing requirements, quality rejections are very high, leading to heavy process scrap.

- Skilled labour. Shortages of specialists or skilled operators impact quality and on-time delivery to customers.

- Resource utilisation. Low utilisation of factory resources significantly impacts day-to-day output and OpEx. Effective use of manpower, machines, materials, and factory space is critical.

- Sustainability. This is now a non-negotiable part of any industrial strategy. Commitment to sustainable practices is essential from a compliance perspective.

| Smart Electronics, Smarter Factories |

| • Electronics fuel smart factories; smart manufacturing, and, in turn, drive electronics innovation • Industry growth: 10% globally, even faster in India • Roadblocks: Shorter product cycles, price wars, old machines, scrap losses, skill gaps, and sustainability demands • The shift: Connect→Integrate→AI-power • True success=process+technology+people working in sync |

The transformation

When we ask what smart manufacturing truly means for the electronics industry, the answer begins with recognising the factory challenges we face and identifying cost-effective technology solutions to solve them. From management’s view, competitive pressures, operational inefficiencies, economic constraints, and shifting market demands all push manufacturers toward digital transformation. Technologies such as AI, big data, and connected systems serve as foundational enablers.

- Connecting AI with smart products drives predictive capabilities

- Linking AI with big data enables advanced analytics

- Integrating big data with connectivity results in real-time data capture and monitoring

Yet, transformation is not limited to machines and technology. Operators on the shop floor play a pivotal role. Without proper training and mindset change, even the most advanced technologies cannot deliver expected outcomes. Thus, smart manufacturing rests on three pillars: process, technology, and people.

The transformation journey begins with consulting and extends across the smart manufacturing cloud. This journey can be visualised in three progressive stages:

- Digital manufacturing. Focuses on connected machines and factories. Connected machines require a communication architecture. Non-communicable and legacy machines need retrofitting with sensors and PLCs to become communicable.

- Digital factory. Focus shifts to system Integration, using MES (manufacturing execution systems), ERP (enterprise resource planning), and PLM (product lifecycle management). Seamless interaction among these layers enables a truly connected environment.

- AI-driven manufacturing. Captured data is leveraged for data-driven decision-making, supporting quality control and strategic business planning. Tools like machine vision and AI-powered predictive maintenance enhance production, ensure quality, and improve operational reliability.

From a data-driven perspective, these three phases are also known as Connect, Collect, and Consume.

Steps to make the transformation real

To begin, a factory’s current state must be assessed across procurement, inventory, production, supply chain, maintenance, and quality. Capturing data, analysing it to find performance gaps, and identifying improvement opportunities is critical. Decisions must be justified with a clear return on investment (ROI).

Once the groundwork is laid, the focus shifts to process-level transformation. Every process, from manufacturing and assembly to quality inspection and material handling, must be simulated and analysed. Simulation tools, ranging from Level 0 to Level 5, ensure layouts and flows are optimised. Both static and dynamic simulations play roles depending on applicability. This includes simulating human-dependent activities to ensure expected output.

Whether greenfield or brownfield, factory setups must be virtually validated. Physical and virtual validation ensures design, space, equipment, and processes align with production goals. A communication network, such as 5G, Wi-Fi, or wired internet, must be selected to ensure seamless machine-to-machine interaction.

The goal is to create a comprehensive, integrated ecosystem that connects manufacturing systems, factory operations, and decision-making capabilities.

Operator training is equally vital. Experienced workers may know the process, but new operators must quickly learn to avoid quality errors and achieve required performance. Tools such as digital work instructions, AR/VR, and interactive platforms enable just-in-time training, even without formal classrooms.

On the execution side, MES platforms are central. They manage production orders, track workflows and OEE (overall equipment effectiveness), handle quality and maintenance, and monitor energy usage. Real-time dashboards provide visibility into factory operations.

For older machines, especially in brownfield settings, retrofitting is essential. Sensors can convert even 60- or 70-year-old machines into data-generating units. Newer machines with built-in communication must be integrated using suitable protocols such as MQTT, Modbus, ProfiBus, ProfiNet, and OPC-UA. Once connected, this data is then fed into AI-powered systems for predictive maintenance and quality control.

This brings us to the latest approach—6D Smart Manufacturing Transformation, which includes six pillars:

- Factory scanning. Validating that physical construction aligns with digital designs

- Change alerts. Flagging early deviations for timely corrective actions

- Cost anchoring. Tracking how costs accumulate during physical and digital implementation

- Environmental monitoring. Leveraging data for environmental responsibility and compliance

- Sustainability. Aligning with India’s national agenda for sustainable manufacturing

- AI integration. Using AI to manage complexity, drive insights, and support continuous improvement

Industries are moving forward in their manufacturing transformation journey. This evolution extends beyond digitisation, aiming to create intelligent, agile, and sustainable ecosystems that address the changing needs of automotive, aerospace, and electronics sectors.

Based on a session titled ‘Manufacturing Transformation Vs Electronic Industry’ delivered by Prashant Kumkar, Practice Head Smart Manufacturing, Tata Technologies Ltd, at the EFY Expo held at the Auto Cluster Exhibition Center, Pune, on 16 May 2025. Transcribed and curated by Shubha Mitra, Assistant Editor at EFY.