Your capacitors might be holding you back. Learn how hybrid capacitors are boosting reliability in EVs, servers, and more.

If you’ve ever worked with electronic circuits, you know how important capacitors are. But not all capacitors are the same. Depending on the design and materials used, some can handle higher currents, offer better reliability, or last much longer.

In a standard aluminum electrolytic capacitor, you’ll find a strip of electrolytic paper placed between two aluminum foils. One acts as the anode and the other as the cathode, and they’re rolled together. The paper is soaked in a liquid electrolyte, which helps connect the two foils electrically.

So what makes polymer hybrid capacitors different? The main difference is in the electrolyte. While traditional aluminum electrolytic capacitors use only liquid electrolyte, polymer hybrid capacitors combine a conductive polymer with the liquid. This combination brings a major advantage because it significantly lowers the equivalent series resistance, which means better performance for you.

If you’re designing for high-performance systems, polymer hybrid capacitors also bring advantages over solid polymer types. Polymer hybrid capacitors maintain stable low leakage current after reflow soldering due to their self-healing function. Their high voltage tolerance and open failure mode make them ideal for decoupling in automotive systems.

Global leaders in passive components such as TAIYO YUDEN have developed extensive polymer hybrid capacitor lines tailored for demanding applications. Click here to explore examples ofTAIYO YUDEN’s extensive hybrid capacitor range. Refer to Video 1 (below)to see how TAIYO YUDEN is improving hybrid capacitors for today’s technology.

Introduction to Conductive Polymer Hybrid Aluminum Electrolytic Capacitors

Tiny Part, Big Role

We rely on conductive polymer hybrid aluminum electrolytic capacitors because they meet the real-world demands of modern electronics. Whether we design for cars, industrial machines, network systems, or everyday devices, these capacitors give us the performance and reliability we need.

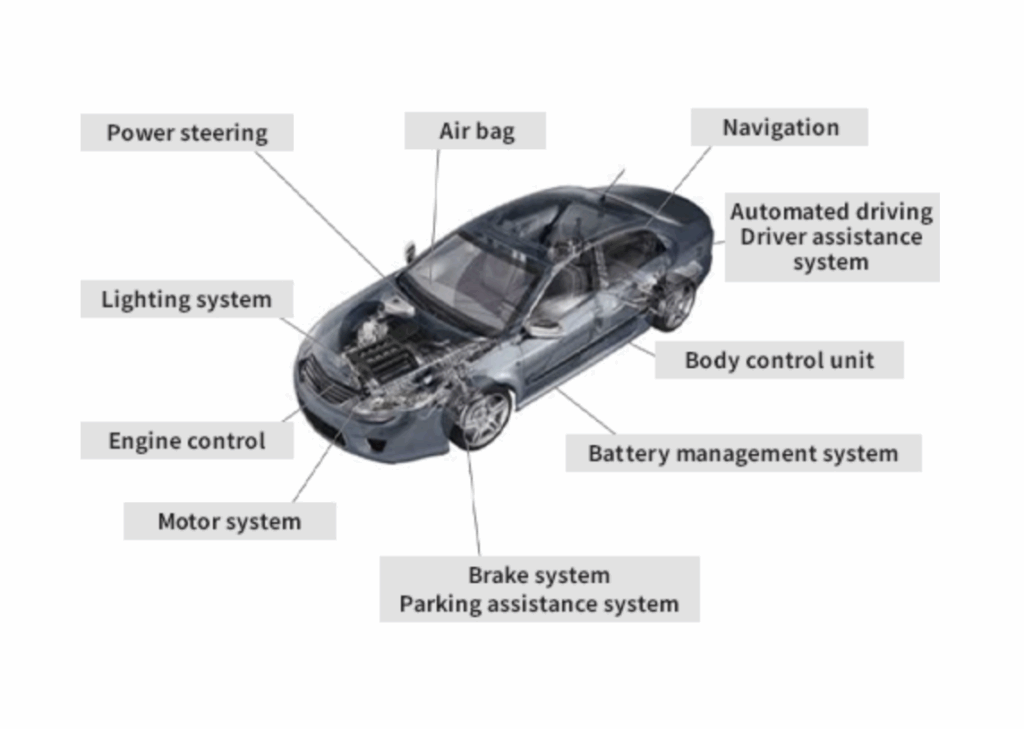

In the automotive world where electrification and autonomous features are growing fast, we see a big increase in power demands, especially for systems like engine control units (ECUs). These units deal with fluctuating voltages, high loads, and tough environments. That’s where hybrid capacitors come in. They help us stabilize ripple current, decouple power supplies, and resist vibration. Since they meet the AEC-Q200 standard, we use them confidently in ECUs, DC/DC converters, and inverters. They are also great for features like ADAS, electric power steering, automatic braking, and integrated starter generators (ISGs) thanks to their small size, heat resistance, and high performance. We also offer a product lineup designed to support future 48V system implementations.

Click here to see how vehicles are changing, why more people are using these parts around the world, and how global leaders in passive components help meet today’s needs.

In industrial electronics, we turn to hybrid capacitors for systems like SMPS units, motor drives, and machine vision equipment. These setups need to run for long periods without failing. Hybrid capacitors help us meet that goal by handling high ripple currents, offering low ESR, and staying durable over time, keeping things stable and reducing the need for frequent maintenance.

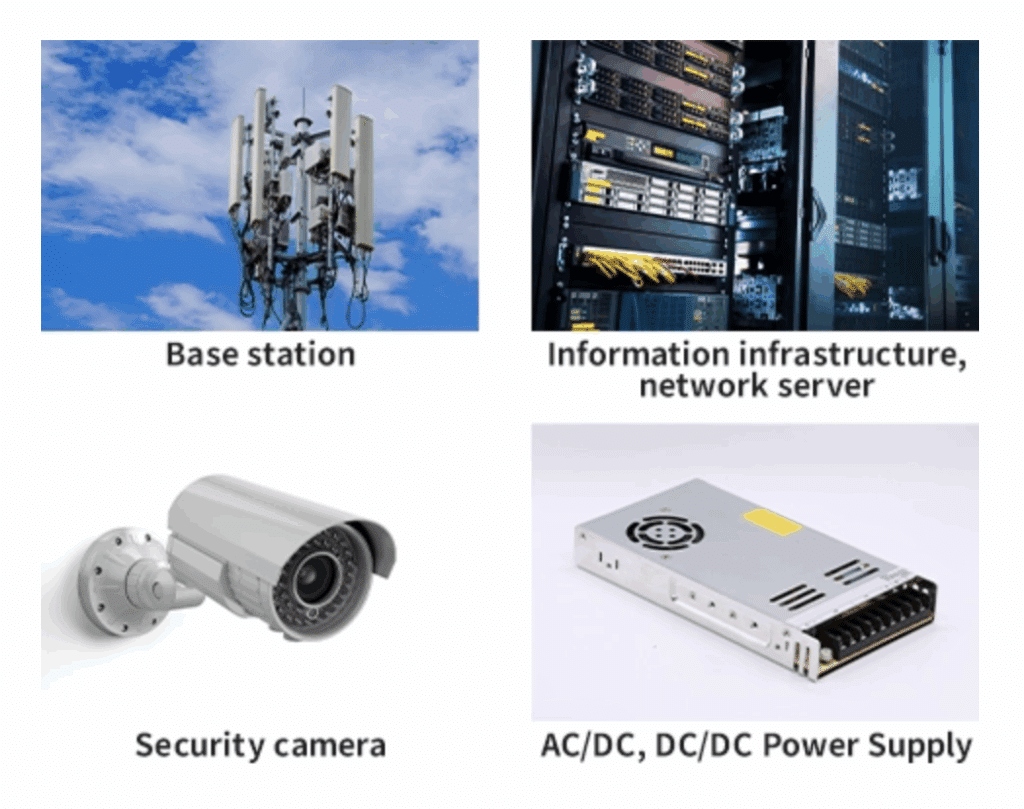

Our telecom and IT systems like servers, switches, and routers, also benefit from hybrid capacitors. Given the continuous operation of these systems, thermal and noise challenges are persistent. Polymer hybrid capacitors, with their high capacitance and low ESR, effectively mitigate these issues and support sustained system uptime.

Even in consumer electronics where space is tight and efficiency matters, we choose hybrid capacitors for their compact design and reliability. Their small surface-mount packages give us the high capacitance we want without compromising performance or safety.

TAIYO YUDEN’s Differentiation

TAIYO YUDEN offers a wide portfolio of hybrid aluminum electrolytic capacitors with one of the industry’s broadest selections of case sizes, ranging from 5 x 5.8 mm to 12.5 x 16.5 mm. The larger sizes support higher capacitance and higher ripple current, and meet the growing demands of power electronics across automotive, industrial, telecom, and consumer applications.

These polymer hybrid capacitors combine the benefits of aluminum electrolytic and conductive polymer technologies. They use aluminum oxide as the dielectric film, aluminum foil electrodes, and a hybrid liquid/polymer electrolyte. This structure results in low ESR, high ripple current capability, low leakage current, and stable performance across a wide temperature range. They are AEC-Q200 qualified and show minimal leakage change after reflow soldering.

These capacitors offer real-world advantages such as stable performance in extreme temperatures, long operational life, and high current handling. Compared to standard aluminum electrolytic capacitors or solid polymer capacitors, hybrids deliver better reliability, improved noise reduction, and typically fail in an open-circuit mode which eliminates the need for extra circuit protection.

The HVK and HTK series offer high-rated voltage and long lifespan at 125°C, making them suitable for automotive, telecommunications, and high-performance industrial systems.

The HVX and HTX series offer high-rated voltage and long lifespan at 135°C. They are specifically designed for automotive applications and support 25V, 35V, 63V, and 80V. The HTX and HTK series are vibration-resistant types, verified to withstand acceleration up to 30G.

The HV1 and HT1 series offer long lifespan at 105°C. The HT1 series features a vibration-resistant design, making it suitable for telecommunications equipment and high-performance industrial systems where vibration is a concern.

The HVL and HTL series offer long lifespan at 125°C. The HTL series features a vibration-resistant design, making it suitable for long-term use in automotive, industrial, and consumer applications.

The HVQ and HVY series support high-temperature operation at 150°C. The HVY series, in particular, offers a long lifespan at 150°C and is suitable for equipment requiring high-temperature performance.

TAIYO YUDEN AEC-Q200 Conductive Hybrid Capacitors feature superior electrical performance with low equivalent series resistance (ESR) and support high ripple current. These capacitors are qualified to the AEC-Q200 standard for automotive use and are vibration resistant up to 30G. They also deliver low ESR, contributing to long product life. These AEC-Q200 hybrid capacitors are suitable for a wide range of automotive applications, including powertrain systems, power steering, body control modules, battery management systems (BMS), brake systems, parking assist, infotainment, advanced driver-assistance systems (ADAS), and more.

Polymer hybrid capacitors offer a powerful combination of low ESR, high ripple current capability, and strong reliability, making them a key component for today’s demanding electronic designs. By leveraging both liquid and conductive polymer electrolytes, they address the performance and durability challenges faced by standard aluminium electrolytic and solid polymer capacitors. Their ability to operate in extreme temperatures, withstand vibration, and deliver consistent performance over time makes them an ideal choice for automotive, industrial, telecom, and compact consumer applications. With industry leaders like TAIYO YUDEN providing a wide range of sizes and ruggedized series, engineers can confidently design systems that are more compact, robust, and efficient—ensuring stability, safety, and longevity in an increasingly electrified world.

| Design Challenges and Solutions |

| • Size Constraints: Hybrid capacitors are larger than MLCC or tantalum capacitors, making it difficult to fit them into compact designs with strict space limitations. Solution: Use SMD (surface-mount device) versions of hybrid capacitors and optimize PCB layout to improve component placement and save space. • Balancing Capacitance and ESR: Solutions: • Thermal Stability and Lifespan: ○ Based on detailed environmental conditions, we conduct lifetime simulations for components and provide tailored proposals. |