How can you design smaller and smaller electronics while managing the challenges of power electronics? The answer: MLCCs (Multilayer Ceramic Capacitors). What are they? Why are they important? How to select the right ones? To shed light on these questions, we spoke to MLCC experts at Taiyo Yuden, and here’s what we discovered…

Multilayer Ceramic Capacitors (MLCCs) are highly innovative forms of capacitors, especially when it comes to delivering performance within super-small packages. MLCCs consist of many thin layers of ceramic dielectric material stacked with alternating layers of conductive metal electrodes. This multilayer structure enables MLCCs to deliver high capacitance in a small size, making them ideal for compact and high-performance applications.

Naturally, the level of miniaturisation requires advanced R&D and manufacturing capabilities, and few leading brands, such as Taiyo Yuden, are able to produce a wide range of MLCCs. In fact, for firms like Taiyo Yuden, MLCCs are one of their core products. The MLCCs enable them to have a product portfolio that can cater to advanced applications like IoT, 5G and vehicle electrification. Their small size and ability to filter noise and stabilise signals make MLCCs useful across a range of fields, including consumer electronics, automotive, industrial equipment, and RF systems.

Leaders in MLCCs such as Taiyo Yuden, also develop other capacitors and energy devices to serve the growing demands of its target markets. Click here to view an example of the wide range of MLCCs provided by leaders like Taiyo Yuden, which enable design engineers to develop better smartphones, IoT devices, and even EVs and cars.

MLCC: Understand the Technology

Performance of MLCCs depends on the number and thickness of the ceramic layers. As layer thickness decreases, more layers can be stacked to increase capacitance without enlarging the device. The ceramic material used typically includes high dielectric constant oxides like titanium dioxide, while electrode materials include nickel, silver, or palladium. MLCCs are available in two main types: temperature-compensated (Class 1) and high-dielectric-constant (Class 2), each defined by specific industry standards.

Thanks to their Low ESR and Low ESL characteristics、MLCCs are used for power supply filtering, signal coupling, frequency stabilisation, and noise suppression. Manufacturers have pushed the technology further by stacking up to 1000 ceramic layers to meet the high-capacity demands.

Why These Tiny Parts Matter More Than Ever

As mentioned earlier, Multilayer Ceramic Capacitors (MLCCs) are now used more and more in many industries because new devices need better and smaller parts. In gadgets like phones, tablets, watches, and laptops, everything is getting smaller and smarter. These MLCCs help by giving steady power, reducing noise, and saving space on the circuit. Taiyo Yuden is making these MLCCs even smaller and stronger so they can work well in hot places, fit into thin devices, and stay reliable in cars and other machines. Refer to Video 1 (below) to see how one of the global leaders in passive components is improving MLCCs for today’s technology.

In the automotive sector, the transition to electric and hybrid vehicles has increased MLCC usage. Electric vehicles now contain tens of thousands of MLCCs to support powertrain systems, battery management, infotainment units, and advanced driver-assistance systems (ADAS). As regulatory bodies push for mandatory safety features, the adoption of ADAS continues to grow, directly boosting MLCC demand. The shift toward autonomous driving further increases this requirement, as vehicles depend more on electronics for control and operation. Taiyo Yuden offers MLCCs for automotive applications such as powertrain, safety, and body systems including lighting, keyless entry, and electronic mirrors.

Industrial automation and robotics are also major users of MLCCs. With the rise of smart factories and Industry 4.0, these capacitors are critical for use in control units, sensors, industrial computing platforms, and power systems. Their ability to perform reliably under high temperatures and in electrically noisy environments makes them ideal for harsh industrial conditions.

The telecommunication sector is another strong growth area, especially with the global rollout of 5G. MLCCs are vital in maintaining signal integrity, managing power, and filtering noise in base stations, antennas, and high-frequency communication equipment. As 5G infrastructure expands and connected devices multiply, the need for high-performance capacitors becomes more pronounced. Taiyo Yuden, for example, offers MLCCs specifically designed for communication equipment such as cellular phones and wireless applications.

Specialised fields such as aerospace, defense, medical electronics, and railway systems are also adopting MLCCs for critical applications. These include life-support machines, avionics, radar, and signalling systems—where consistent, failure-free operation is essential. For example, Taiyo Yuden offers MLCCs specifically designed Medical Devices classified as GHTF Classes C (Japan Class Ⅲ), and for Medical Devices classified as GHTF Classes A to B,

Click here to get a glimpse of the wise range of MLCCs that brands like Taiyo Yuden offers, and how their websites are designed to help you (R&D engineers) to select the best component for your application.

The illustration below provides an excellent overview of how different types of MLCCs are best suited for different applications. It’s clear that the smallest ones (with lower capacitance) are important for miniature-electronics (IoT, Consumer, Health, etc) and then as their sizes and capacities grow, so do the size of the product(s) where they are needed..

Microscopic Capacitors That Power Modern Devices

As devices like smartphones, wearables, and IoT gadgets become smaller and more complex, the need for compact components continues to grow. Designers face the challenge of fitting hundreds of MLCCs into limited board space while maintaining high capacitance, thermal stability, and electrical reliability. Smaller MLCCs must still perform under high voltage, frequency, and temperature conditions without increasing cost or risk of failure.

This ongoing miniaturisation creates pressure to improve performance without expanding size. Recent high-end smartphones are equipped with approximately 1,500 MLCCs. As devices demand more functions in smaller spaces, traditional capacitor designs struggle to keep up—especially in high-frequency and high-power applications.

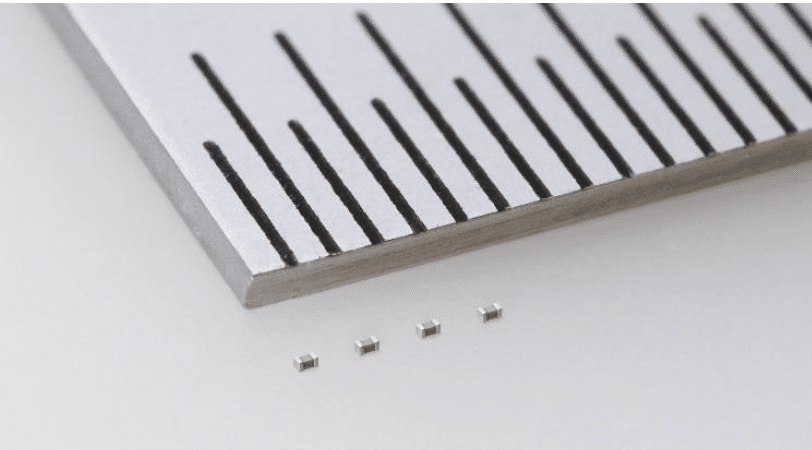

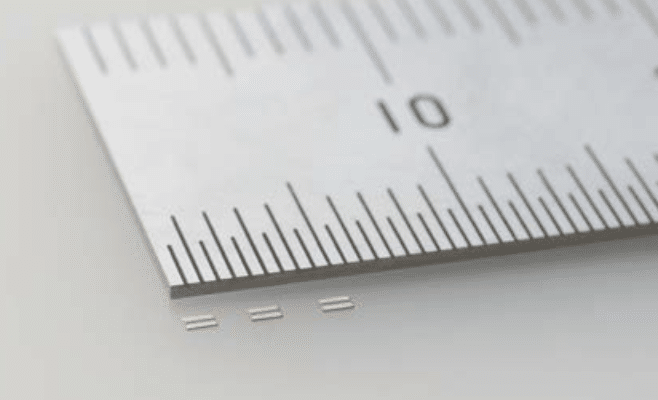

To meet these challenges, brands like Taiyo Yuden have developed advanced materials, high-precision printing, and ultra-thin multilayer technologies that enable consistent production of ultra-small, high-capacitance MLCCs. Their 0201 size high-frequency MLCCs—just 0.25 x 0.125 x 0.125 mm—are about 75% smaller than the previous 0402 models. These are designed for impedance matching in high-frequency circuits used in compact devices like smartphones and IoT gadgets.

So, how are such microscopic components made? The answer lies in three core technologies which players like TAIYO YUDEN have mastered: advanced material development, high-precision printing, and precise lamination. These processes allow them to create dielectric sheets as thin as 1 μm (1/1,000 mm)—about 1/100 the thickness of a human hair.

Click here to view a white-paper by Taiyo Yuden explaining the demand for MLCCs and throwing some light on the type of innovation being done to cater to these new demands.

Ultra-Thin Profiles

As electronic devices become smaller and more advanced, there is a growing need for highly reliable and ultra-thin multilayer ceramic chip capacitors (MLCCs) that can operate in harsh conditions. Achieving thinner internal layers is difficult and requires advancements in dielectric materials, internal electrodes, firing processes, and their integration. These capacitors also need to be compact enough to embed within PCBs or under IC packages, freeing up space for other components.

There is increasing demand for base metal electrode MLCCs with high capacitance, especially in patient monitors, compact security devices, and high-frequency automotive and data center applications. These components must store and release electricity efficiently in limited space. To meet these needs, manufacturers are heavily investing in R&D to improve performance and production methods for next-generation ultrathin MLCCs.

For example, TAIYO YUDEN offers an MLCC product with a thickness of just 0.064 mm, specifically designed for compact devices like smartphones and wearables. It offers effective decoupling for IC power lines in space-limited applications while maintaining low equivalent series inductance (ESL) through lengthwise external electrode placement. This makes it suitable for high-speed, high-density electronics where stable performance is critical.

The MLCC is built using advanced materials and manufacturing technologies, including thinning sheet processes and high-performance dielectric layers as thin as 0.6 μm. With the ability to stack up to 1,000 layers, it achieves higher capacitance without increasing its size.

Record-Breaking Capacitance

Modern digital devices increasingly rely on switching-type power supplies to improve efficiency, but these circuits require large-capacitance capacitors at the output to smooth voltage and maintain stability. Traditional capacitors like aluminum electrolytics offer high capacitance but are bulky and have higher Equivalent series resistance (ESR), making them less suitable for high-frequency applications in compact electronics such as smartphones and smartwatches.

This creates a key design challenge: capacitors in very high capacitance range are usually too large to fit in space-constrained devices. Multilayer ceramic capacitors (MLCCs) address this by offering low ESR, better frequency performance, and much smaller size. They allow engineers to control ripple current effectively while keeping the circuit compact, making them ideal for modern portable electronics.

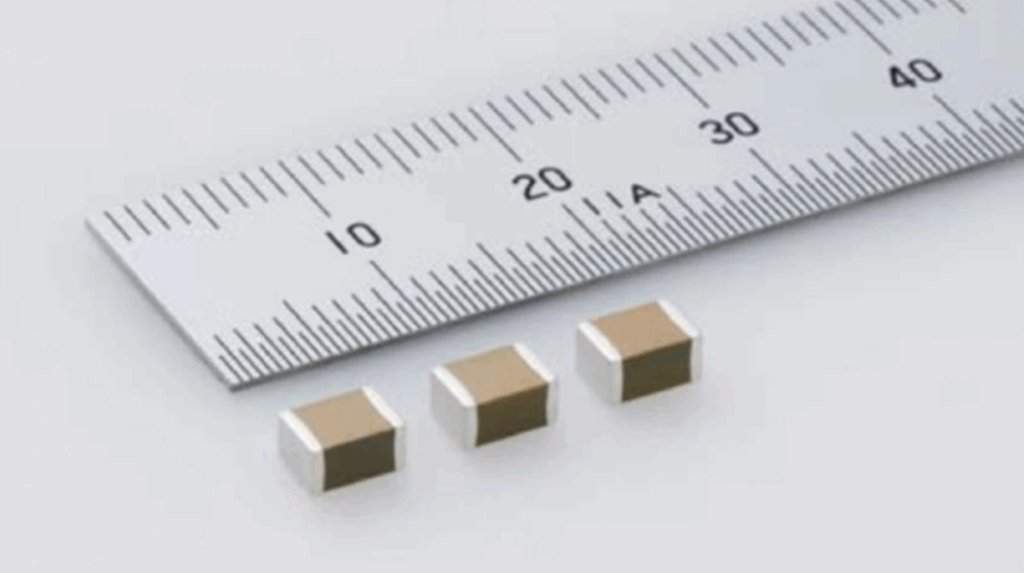

Leaders like Taiyo Yuden have addressed the size and performance limitations of traditional capacitors by advancing their MLCC technology through expertise in materials, thin-film processing, and multilayer design. This has led to the development of compact yet high-capacitance products, including TAIYO YUDEN’s 1,000 μF MLCC in a small 4.5 × 3.2 × 3.2 mm package. Designed for use in ICT equipment and energy-harvesting systems, it enables power smoothing and backup within tight spaces.

There’s Lots More to Come

While we have discussed three types of innovations in MLCCs with examples from TAIYO YUDEN’s product portfolio, brands like TAIYO YUDEN offer a much broader MLCC lineup. These products support a wide range of capacitance values and dielectric types, covering applications from general electronics to automotive systems, all while continuing to reduce size and improve reliability. And, since the R&D and innovation is on-going, expect a lot more exciting MLCCs to come up to power unimaginable applications in the near future.

| What’s Inside an MLCC? |

| MLCCs are tiny but critical components used in all kinds of electronic devices. Here’s a quick look at how they’re made and why materials play a key role. • How They’re Made? MLCCs are built by stacking multiple ceramic dielectric layers with internal electrodes into a compact unit. Each layer can be thinner than 1μm—around 1/100th the width of a human hair. These thin layers allow MLCCs to store more energy in smaller volumes. • Why Materials Matter? Increasing capacitance means stacking more layers, but to keep MLCCs compact, manufacturers use ultra-fine ceramic particles to create thinner dielectric sheets. These nano-sized particles must be uniform in size to ensure consistency in thickness, density, and performance. Any variation can cause defects or reduced capacitance. • How Limits Are Being Pushed? Taiyo Yuden, for example, creates its own materials in-house to meet demanding specifications. Their smallest unit, just 0.25 mm in all dimensions, shows the extent of miniaturization achieved through precise material control. Ongoing R&D aims to support even smaller, higher-performance devices across the electronics industry. Click here to view an informative white-paper that provides insights into why the development of ultra-fine materials is the key to innovating in the field of MLCCs. |

Nidhi Agarwal is a senior technology journalist at Electronics For You. She developed this article with valuable inputs and materials from Taiyo Yuden